Module of Base and Security

GC-Win System has exclusive features which are really powerful for system administrators and very useful for users. From each specific field, usual procedures and queries can be directly accessed; and previously entered values can be screened without typing them. Besides, reports can not only be pre-visualized on each screen and printed out, but can also generate plain files or files with html format.

GC-Win System deals perfectly with integrated security and access to information.

GC-Win System also allows the usage of proprietary authentication or Windows authentication, an outline of different accesses to tables and tasks and the usage of registers of table and fields of the registers. New users can be created according to specific profiles and special commands of access for the administration of the system configuration. GC-Win System enables users to keep a record of the events for future audits.

lightbox Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Module of Production Management

The planning and control of production can determine the manufacturing sequences which make it possible to meet, in due time and form, the production needs, which are originated by pending customer orders, sales forecasts and replacement products according to a minimum stock analysis of finished and semi-finished products.

In order to achieve this, GC-Win System presents, for each manufactured item, a list of procedures and manufacture formulas; including production lot, alternative formulas, etc.

Regarding the resources area, GC-Win System presents the specific time for preparing, manufacture standards, required efficiency, calendars of workers availability for each working shift and holidays which can modify production.

Components

Items Managements

Many types of items can be administered; such as raw material, intermediate programs, finished products, unchanged items, spare parts as well as storage, units of measurement, appreciations, usual suppliers, percentages of participation and distribution, substitutions, etc.

The stock can be administrated by item, lot, storage and location. In order to register any transactions (such as adjustments, inventories, transferences, etc), hand-held may be used.

GC-Win System can determine whether the warehouses are company-owned or external. The latter may be used by clients or suppliers. In each warehouse, distribution of locations can be determined in a 3D space. (Height and plane).

Planning Management

The system enables the user to see a graph of the necessary workers, the evolution of the stock of a manufactured product, of the assembly lines and of the input, thus indicating fixed deliveries and their status (being transported, at the customs, at the plant; current or future) estimated deliveries, minimum stock recovery, etc.

Among the most relevant reports, we can find the report on critical material, on the shortage of materials that could be necessary, on average consumption, on dates of finalization of a given stock and on replacement of inputs. There is also the possibility of applying different scenarios which could have been previously determined.

Assembly Line Operation Management

Manage the attention of the operation of a production line. It allows the entry of the data directly involved in its operation, and can be carried out through the interfaces with peripheral input and / or output devices such as bar code readers, data collectors, scales, electronic signs, laser recorders, etc. , as well as manually. It allows communication with PLC or other devices through the OPC-DA and MODBUS standards, for automatic stop registration and control of process variables.

It also allows users to report on the current status of the assembly line, to detect errors, to have a detailed list of events that lead to a sudden halt or pauses in the production and to track registered products in the browsing history apart from the components, workers and devises involved in the production.

Machinery Management

GC-Win System can register each machine employed in the procedures and its characteristics. It also administers the kind of maintenance required for each machine, indicating a critical status, availability, days, hours and frequency, spare parts (frequency of change of those spare parts) and technical revision. It generates a calendar of maintenance that is taken into account during the planning process; thus,the fulfilment of the calendar can be controlled and registered.

lightbox Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

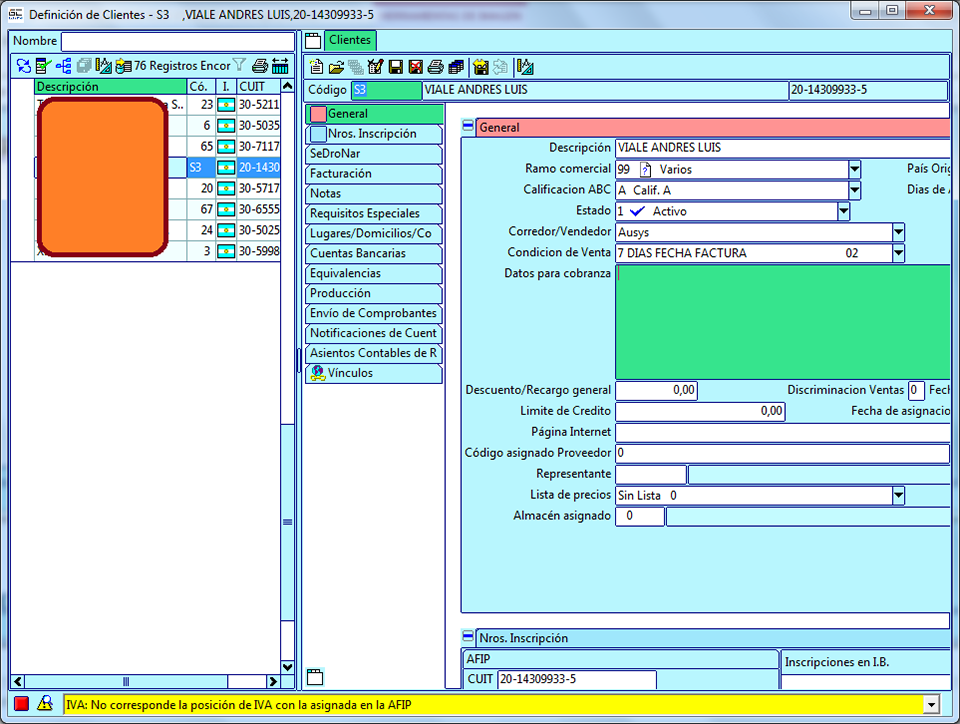

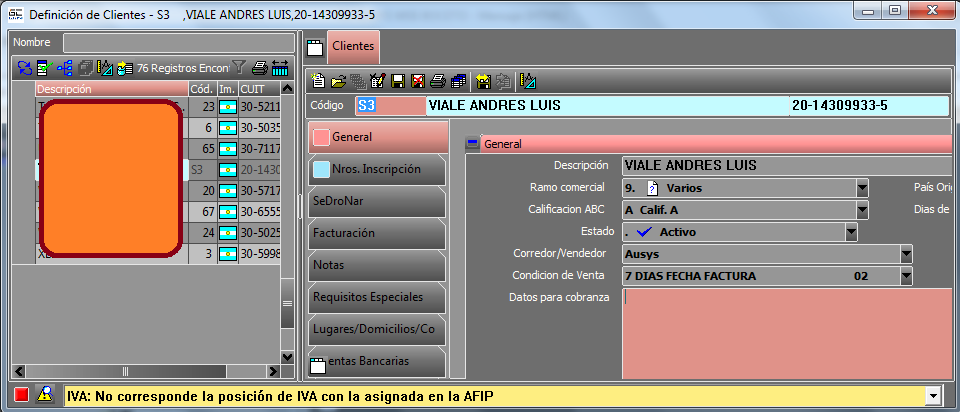

Module of Administrative Management

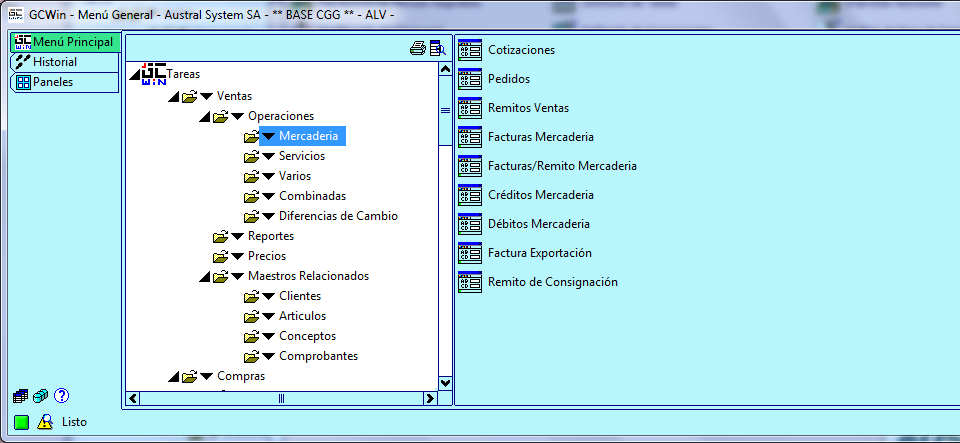

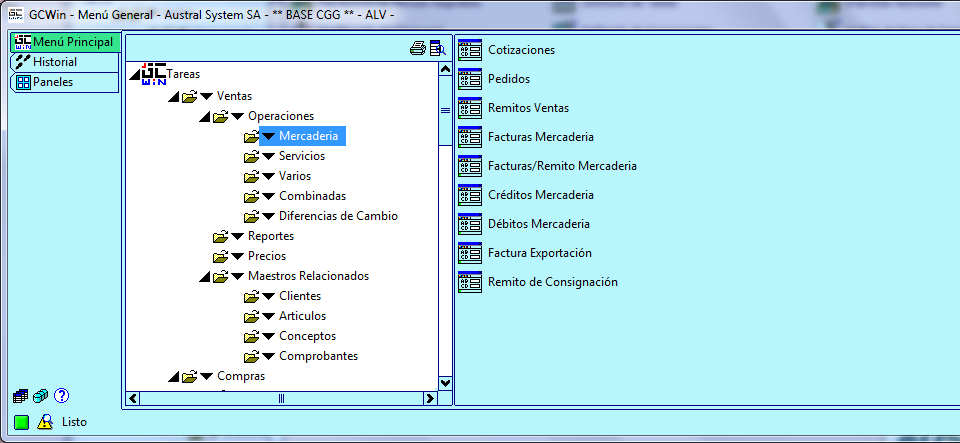

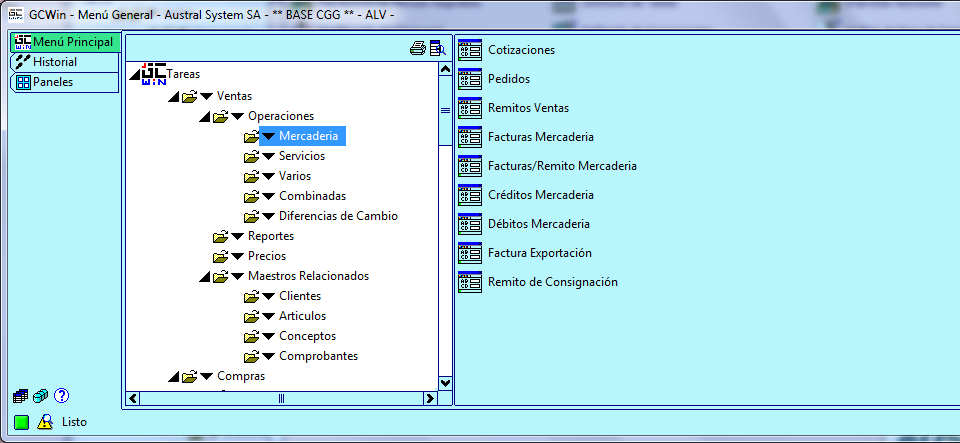

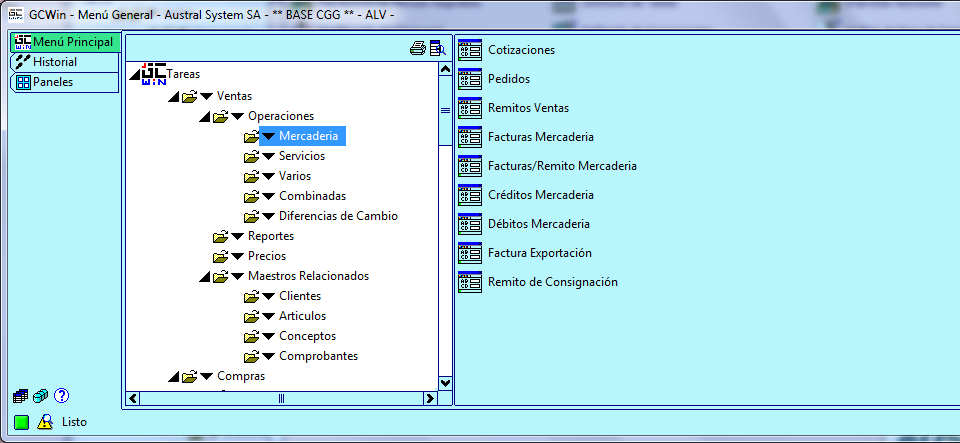

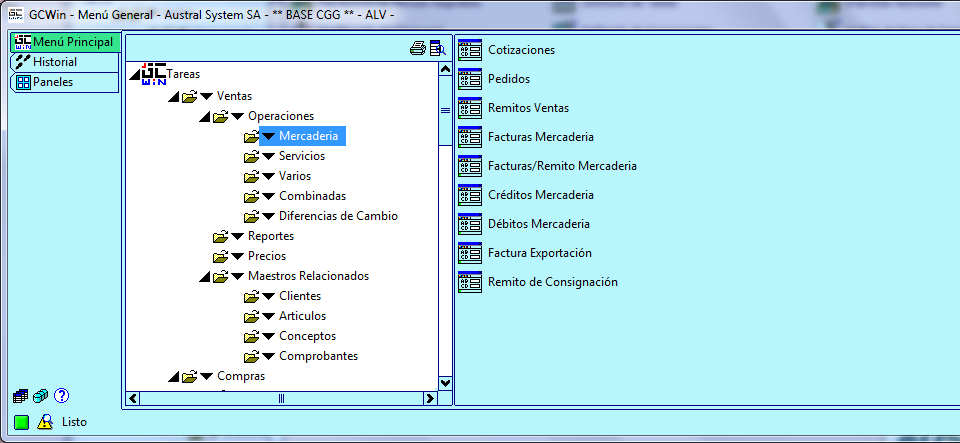

GC-Win System may provide any kind of voucher, traditional ones (suppliers orders, customer orders, invoice) and other administrative devices such as authorization of customer orders and exports.

Besides, there are many circuits in which these vouchers are found; for example: customer order/ invoice or any other circuit employed by the company.

For each circuit, there are different steps and levels of authorization (automatic or manual) that should be complied with so as to move forward in a defined sequence. During each step, and when issuing a voucher, the user can specify the allotment to be generated, the updating of the current account and stock; in this way allowing the movement of income and expenses (collection and payments), the payoff and finally the printing of the voucher.

Components

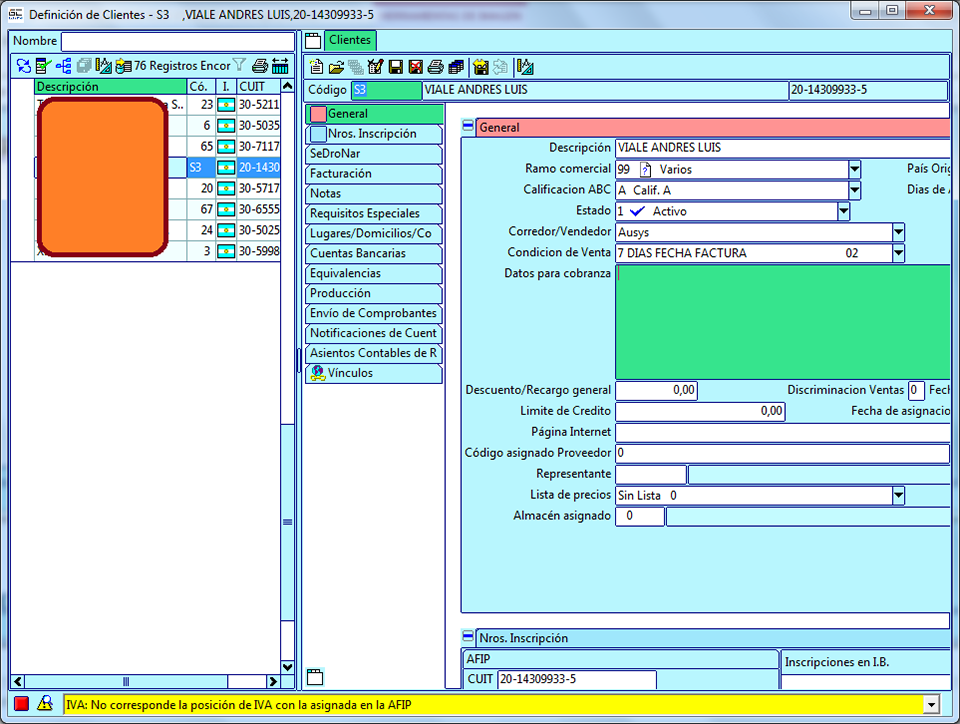

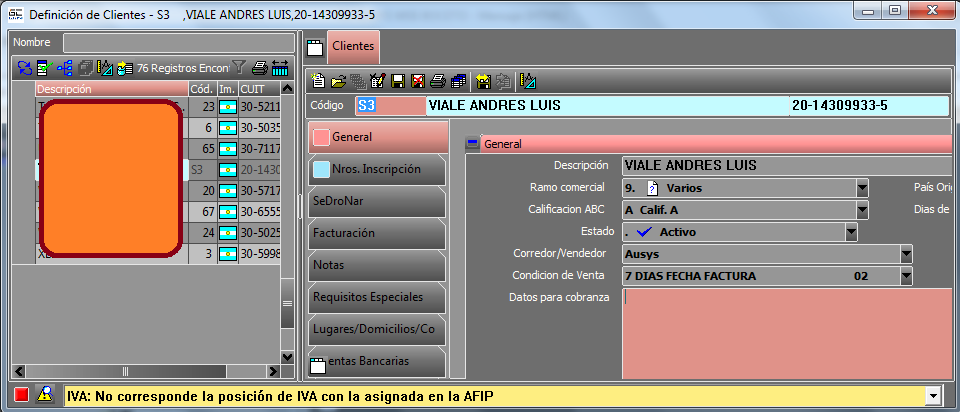

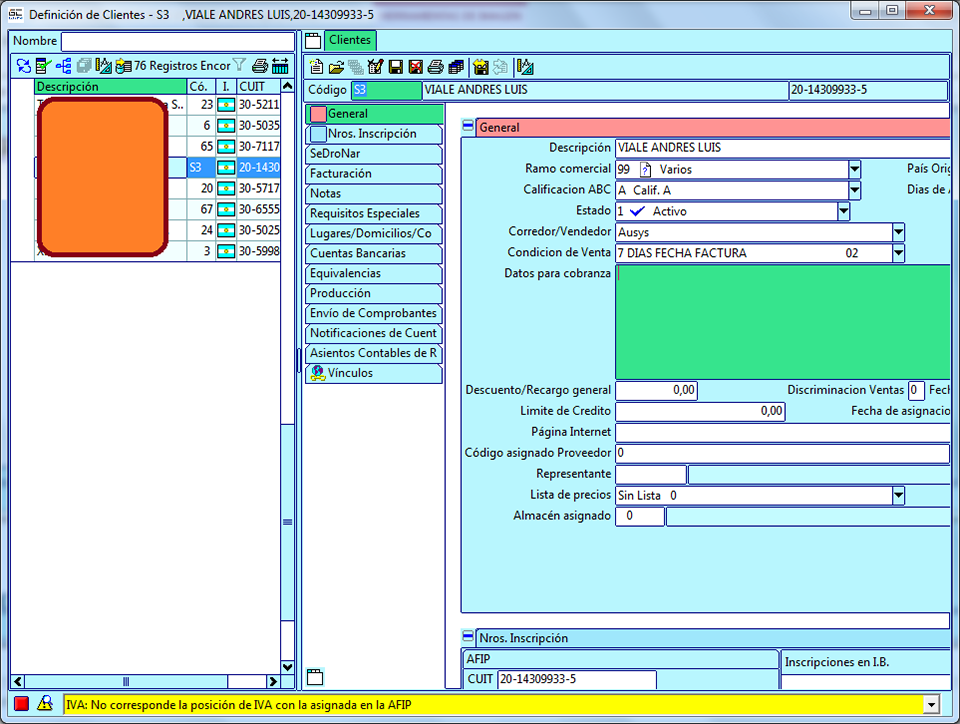

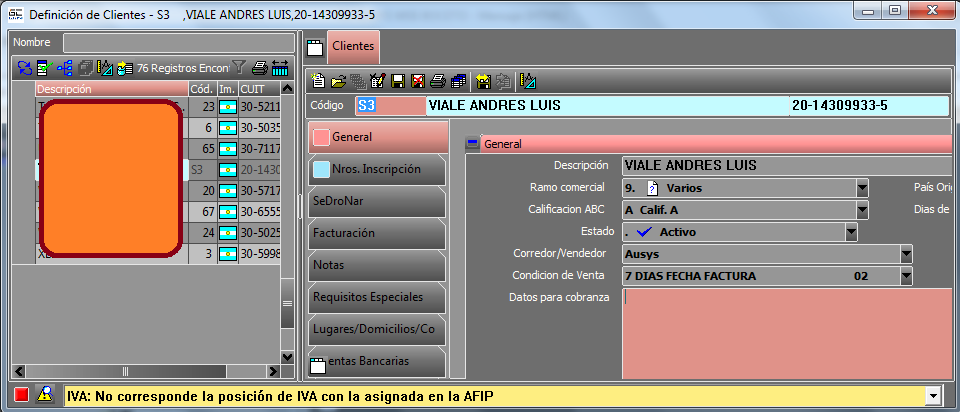

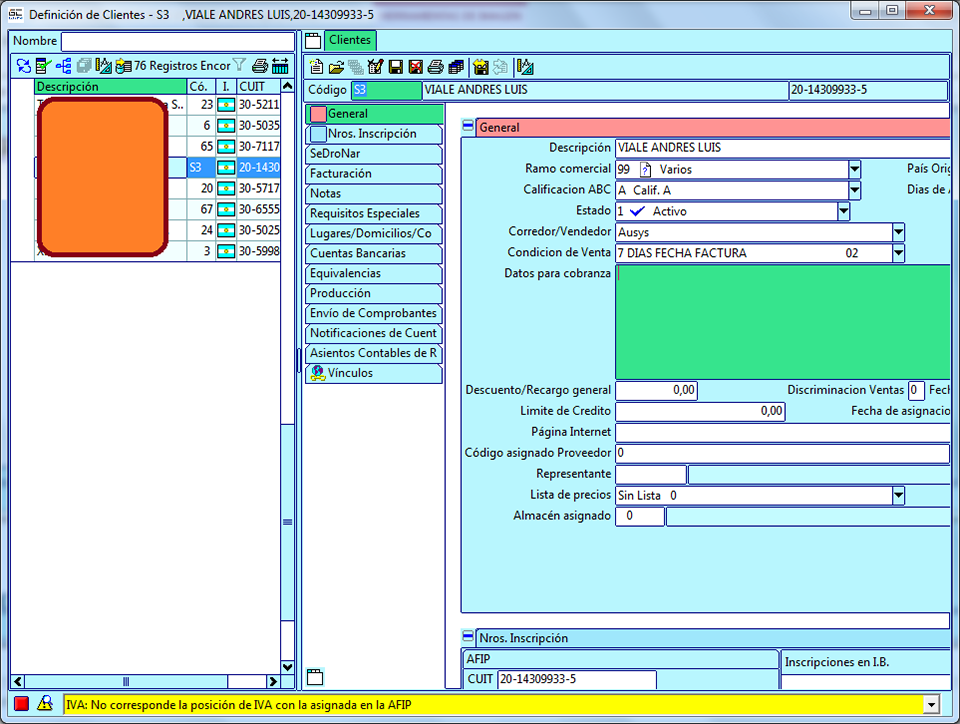

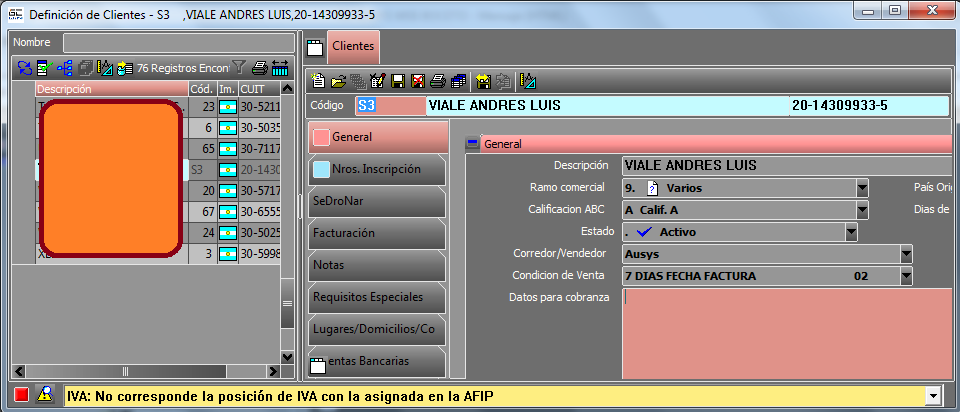

Purchase/ Sale Management

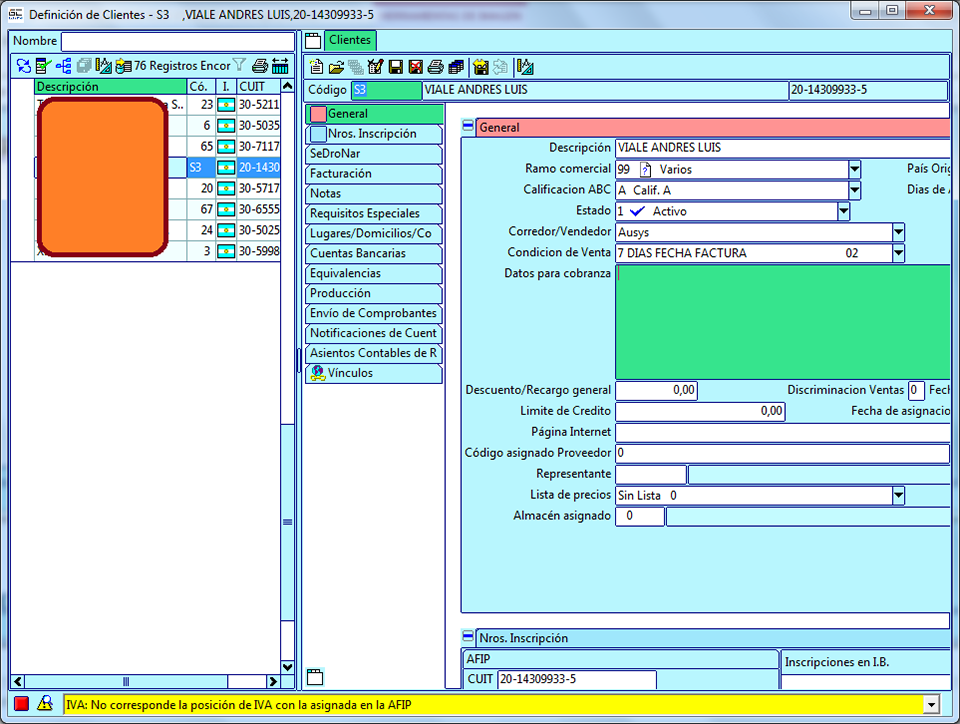

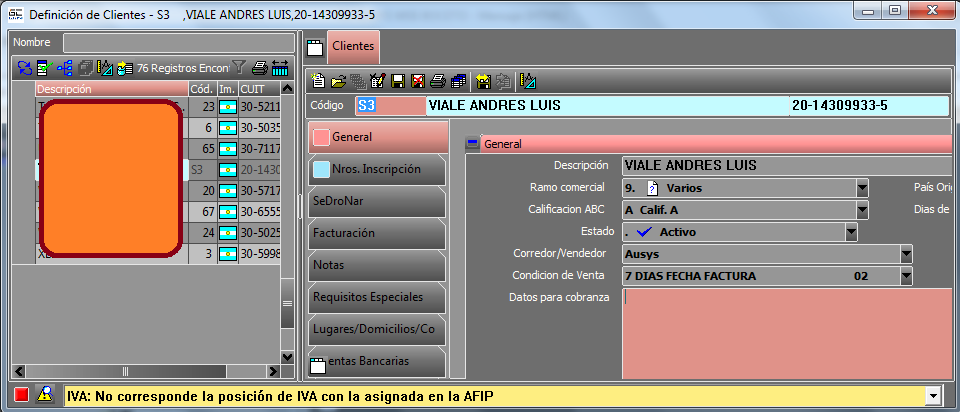

The tasks of administration of clients and suppliers, their particular characteristics, balances and movements in current account, brokers, entry of budgets, orders and remittances, electronic actuation V0, V1, exports, special bonuses and collections are enabled.

The structure of the current accounts provide services such as issuing reports on pending procedures on a given date (even when the corresponding payments were made), obtaining a record of movements (pending payments, balance). This scheme to handle values makes it easy to deal with any kind of “accounting documents”: cheques, tickets, bonuses and any other document.

General Ledger/ Finance Management

Book or accounting entries can be loaded manually, by financial summaries and automatically; ledgers, balances and ending balances can also be achieved.

Among the most important characteristics, we find the ability to feed directly the entered vouchers from the allotment through the generation of cash book/ sales/ purchase entries or other financial summaries; thus allowing its administration to be carried out in many levels.

The detailed list of the stated levels’ structure (for each established company) contemplates the business units together with the cost centers; in this way a financial budget and an associated cash flow can be handled.

Treasury Management

It allows the administration of the values received in collections, endorsements, deposits, and release of own values, including checks, cards, transfers and cash.

Tax Management

It allows VAT and IIBB Perceptions to be made in Sales and their registration in Purchases, as well as the calculation of VAT, IIBB, Earnings and SUSS withholdings in Payments. They contain all the modules of export to the AFIP for agents of Withholding of VAT, IIBB, Earnings and SUSS, of Perceptions and Withholdings. As well as the processing of the Standard of IIBB of AGIP and ARBA. Also RICV, SIRE and SIFERE.

lightbox Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Other Modules

GC-Win System also has other integrated modules which complement their functioning and collaborate with the efficient management of the company.

Components

Peripherals Management

Connections and dialogues can be established with the I/O data equipment within a comprehensive list of peripherals.

Mobile Devices

It allows access to the System from Mobile Devices such as tablets and smartphones, defining roles for remote access to view the information assigned to the role in real time. Other variants allow interaction with the production processes using those devices directly in the plant.

Security Post Management

Inside and outside movements, visits and the entrance of vehicles can be registered.

System Tools

The system, as it is oriented to professionals in the computer industry, enables users to modify existing programs or develop new programs within the same technological environment.

Technical Handbook and User’s Handbook

They provide several degrees of GC-Win System usage related technical and functional information.

lightbox Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal.